Death from acute hemorrhage is a major problem in military conflicts, traffic accidents, and surgical procedures, et al. Achieving rapid effective hemostasis for pre-hospital care is essential to save lives in massive bleeding. An ideal hemostasis material should have those features such as safe, efficient, convenient, economical, which remains challenging and most of them cannot be achieved at the same time. In this work, we report a rapid effective nanoclay-based hemostatic membranes with nanoclay particles incorporate into polyvinylpyrrolidone (PVP) electrospun fibers. The nanoclay electrospun membrane (NEM) with 60?wt% kaolinite (KEM1.5) shows better and faster hemostatic performance in vitro and in vivo with good biocompatibility compared with most other NEMs and clay-based hemostats, benefiting from its enriched hemostatic functional sites, robust fluffy framework, and hydrophilic surface. The robust hemostatic bandages based on nanoclay electrospun membrane is an effective candidate hemostat in practical application.To get more news about stop the bleed, you can visit rusuntacmed.com official website.

Acute hemorrhage is one of the greatest causes of death each year around the world1. A practical prehospital care solution for acute hemorrhage control, especially in the case of warfare, catastrophes and accidents, is urgently needed and is characterized by high clinical demand and large market potential2,3. Rapid effective hemostatic material application in initial hemorrhage phases can lead to an extended rescue time, resulting in a decline in high mortality rates due to excessive bleeding2. However, it is still challenging for most hemostatic materials to quickly and safely control hemorrhage from severe bleeding wounds or cuts1,4. The desired hemostatic materials must be designed and developed to achieve rapid definitive hemostasis for both noncompressible (visceral organs) and compressible (cervical, trunk and head regions near the heart and brain) massive bleeding, both of which involve fatal bleeding and are causes of equal concern4,5,6.

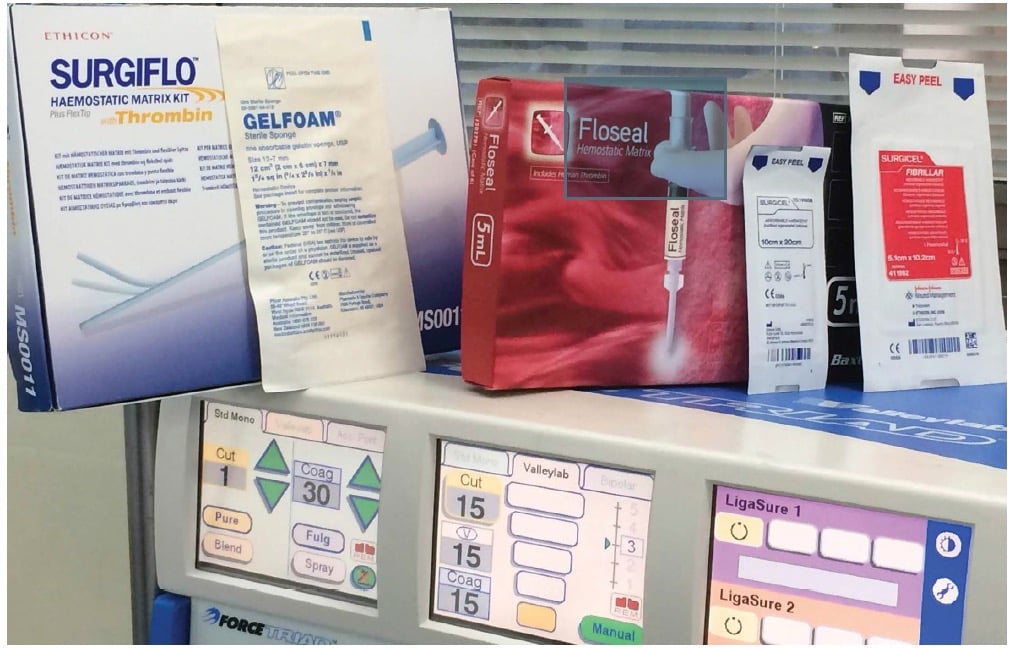

To date, various hemostasis products have been reported, including injectable glues (gelatin4), hemostatic bandages (polymer composites7 and cellulose fabrics8), and procoagulant powders9 (siliceous oxides10 and inorganic clays11,12). Zeolites and clays, the main components of Z-Medica products (Clotting Sponges, Clotting Gauze (ClG) and Combat Gauze (CoG), are widely accepted as effective hemostats6,13. Clays can accelerate the stoppage of bleeding by cooperating with physical hemostatic functions, which facilitate plasma absorption to increase blood cell concentration, and with endogenous hemostasis pathways for negatively charge-stimulated clotting factors13,14,15. Generally, most traditional clay hemostatic materials are in the form of a powder (requiring dressing with gauze) or a clay powder-impregnated gauze (easily detached due to poor adhesion)6,16. Although clays have shown effective hemostatic performance, prolonging the rescue time, the application of clay particles to bleeding wounds may cause inflammation in surrounding tissues and distal thrombosis in vivo13,17. Therefore, it is important to develop membranes or other alternative materials to replace these powder-based materials.

Hemostatic clay particles can be connected by polymers to transform clay powders into clay membranes for acute hemostasis. A few types of biomaterials using nanoclays have been developed as effective hemostats, including hydrogels (e.g., gelatin/polyacrylamide (PAAm)/laponite hydrogels18) and sponges (e.g., graphene-kaolinite or graphene-montmorillonite composite sponge14,19), which are strict and complicated treatments with high costs as medical hemostats. Hydrogels and sponges show good shape memory but poor mechanical strength due to their inherent interconnected macroporous structures, and polymer binders fill and block the clay pores and layer gaps, causing low clay utilization as active components6,16. Electrostatic spinning is one of the most commonly used membrane synthesis methods; this method can be incorporated with nanoclays and enables the easy preparation of light, fluffy, and soft membrane materials20,21,22. Pure polymer electrospun membranes will sharply spontaneously shrink within a short time after preparation23, similar to the contraction of cell membranes, which may have potential applications in emerging technologies (flexible electrodes24 or stretchable materials25,26); however, reducing the effective area of the membrane will increase costs and decrease hemostasis capability. Thus, an ideal design for clay hemostatic membranes should be developed with the characteristics of safety, rapid hemostasis, high active component utilization and a robust antishrinking framework27,28,29.