Cartridge seals are an essential component in many industries, including manufacturing, chemical, and petroleum. They play a crucial role in maintaining the integrity of equipment by preventing leaks, contamination, and the loss of valuable fluids. In this article, we will delve into what cartridge seal is, how they work, and their importance in various industries.

What Are Cartridge Seals?

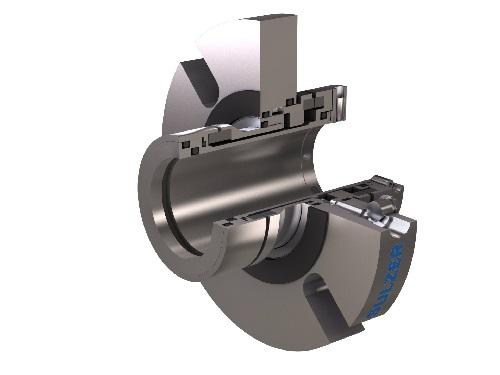

A cartridge seal is a pre-assembled seal that consists of a rotating component, a stationary component, and a spring mechanism. It is designed to be easily installed into equipment, such as pumps, mixers, and compressors, and provides a reliable sealing solution for both low and high-pressure applications.

Cartridge seals offer several advantages over traditional packing seals, including increased sealing efficiency, reduced maintenance, and improved safety. They are also more environmentally friendly than packing seals, as they do not require regular replacement or lubrication.

How Do Cartridge Seals Work?

Cartridge seals work by creating a seal between a rotating shaft and a stationary housing. The spring mechanism applies pressure to the seal faces, which creates a tight seal and prevents the escape of fluids. The seal faces are typically made of a hard material, such as ceramic or tungsten carbide, and a soft material, such as carbon or elastomer.

The design of cartridge seals allows for a quick and easy installation, as they are pre-assembled and do not require any special tools or expertise. They are also designed to be self-aligning, which means that they automatically adjust to any shaft misalignment that may occur during operation.

Why Are Cartridge Seals Important?

Cartridge seals are important because they provide a reliable sealing solution for equipment in various industries. In manufacturing, they are commonly used in pumps and mixers to prevent leaks and contamination. In the chemical industry, they are used to seal hazardous fluids and prevent environmental damage. In the petroleum industry, they are used in pumps and compressors to prevent the loss of valuable fluids and ensure safe operation.

The importance of cartridge seals extends beyond their sealing capabilities. They also offer several benefits in terms of maintenance and safety. Cartridge seals require less maintenance than traditional packing seals, as they do not need to be replaced or lubricated as frequently. They also offer improved safety, as they are less prone to leaks and can help prevent equipment failure.

In conclusion, cartridge seals are an essential component in many industries, providing a reliable sealing solution for a range of applications. They are easy to install, require less maintenance than traditional packing seals, and offer improved safety. If you work in an industry that uses equipment that requires sealing solutions, it is crucial to understand the importance of cartridge seals and how they can benefit your operations.