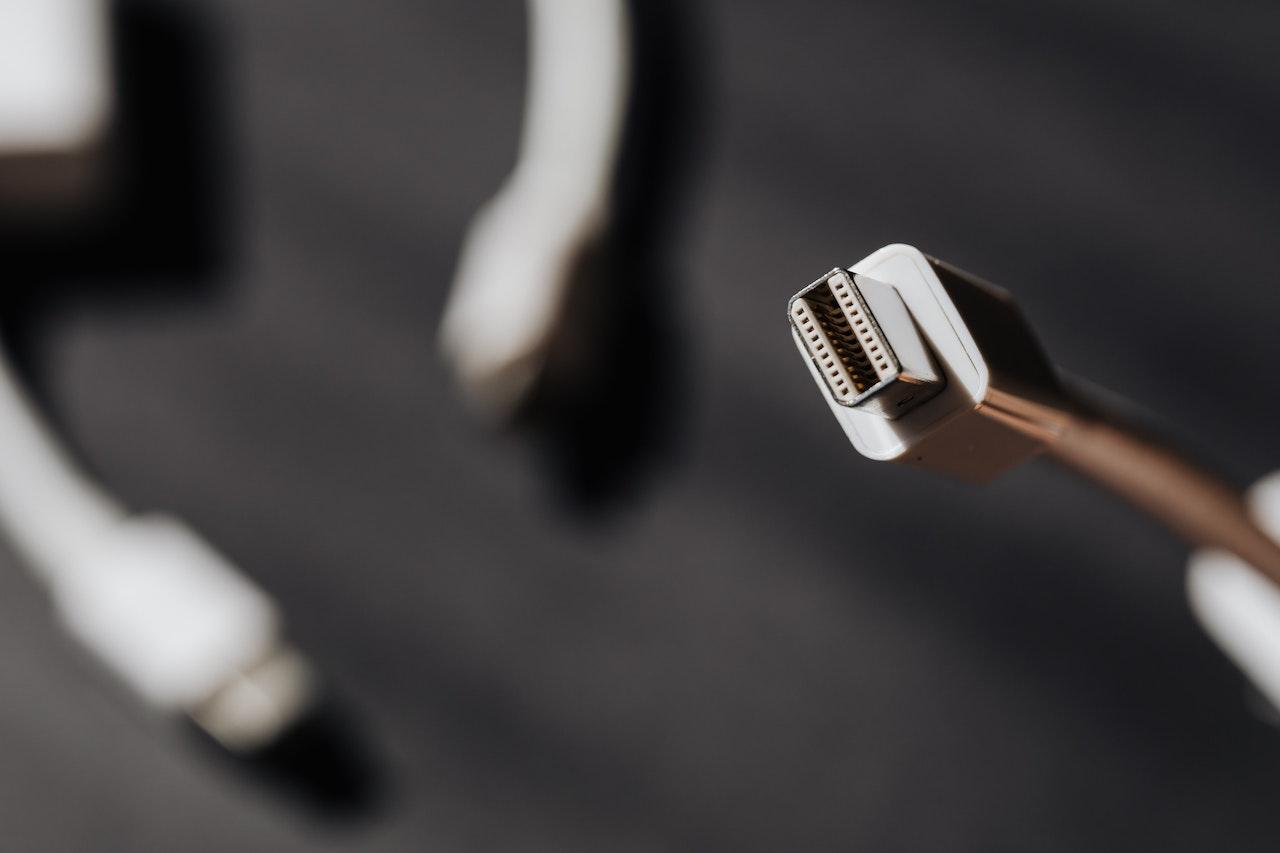

A cable assembly is made up of various types of cables that vary in construction, size, length, and color. Original Equipment Manufacturers (OEMs) typically use pre-terminated cable assemblies when mass-producing kits to hasten and ease installation.

Conventional wires may function in complex applications, but they typically fall short.

When utilized improperly in critical applications, such as military bases, large industrial manufacturing lines, or medical equipment, a custom USB cable assembly could have disastrous effects. Even seemingly simple electrical systems, like a home theatre system, require a special cable assembly to function properly, deliver, and be both compact and user-friendly.

Consequently, custom cable assemblies created especially for the task at hand are a useful option for Sinnhong in a multitude of industries, including automotive, utilities, aircraft, security, and telecommunications.

Appropriate resources

The finished product will be superior to the basic materials. When you select a custom cable assembly, you have more choice over the building materials. The cable harness manufacturer, for instance, will be able to choose the best materials for the product and specify the insulations, shield, and jacketing material to meet the application.

Control over the material sourcing and manufacturing process is vital when items are used in critical applications like the medical sector.

Accuracy

It can be difficult, if not impossible, to locate a ready-made cable assembly that satisfies the requirements of your project. However, according to the design's parameters, custom cables are produced.

The wires might, for example, be color-coded or labeled to lessen the risk and guarantee a perfect match from production to installation.

Each can also be constructed to the precise length required for the project, ensuring a clean setup and avoiding the need to conceal extra wires and connections.

Quantity

By using custom cable assemblies, the maker can precisely order the number of cables required for the application. It is also possible to tune the precise count for the conductor, stranding, and size.

Utilizing the correct quantity will reduce waste and ensure that you have the right number of cables when the assembly is complete.

Quality assurance

Cables used in high-stakes applications cannot afford to fail. The custom assembly will go through significantly more rigorous testing than off-the-shelf products to ensure uniform operation and quality.

To prove that the cable has been put through the necessary testing before assembly, the cable manufacturer can offer the test data that is required, such as tolerances, electrical characteristics, temperature performance, and chemical exposure resistance.

The cable manufacturer should test the product in the environment where it will be used to make sure a particular collection of components can survive the elements. After that, any attributes that require adjustment can be done so.

Higher effectiveness

Custom cables usually perform better than standard cables because of the meticulous manufacturing process.

Custom cables can also incorporate many features like power, signal, video, and cable shielding into a single cable because they are created to order. These customized solutions are ideal for security industry applications like surveillance systems because they are built for unmatched performance and take up less space.

Reduce time and costs.

At first, you might think that selecting a pre-made cable and connecting it straight to your equipment will be less expensive and simpler. These wires normally won't work, excluding the usage. Instead of attempting to convert regular wires, working with a specialized cable maker to build the correct configuration would have saved time and money.

Even though customized solutions could be more expensive initially, enhanced performance and durability will allow you to save money in the long run by lowering the frequency of part replacement. To further save costs, several cable manufacturers now offer added services like laser labeling and design advice.

You can always trust Sinnhong for Custom USB Cable Assembly.