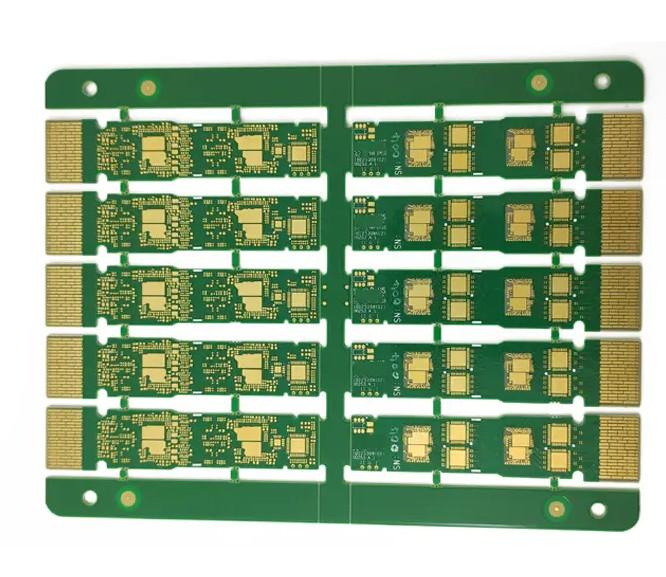

In the realm of advanced PCB manufacturing, Rocket PCB stands as a prominent player, specializing in the production of Gold Finger PCBs. As a trusted manufacturer and supplier, Rocket PCB caters to a wide spectrum of needs, offering gold finger PCBs, long-short gold finger PCBs, and staged gold finger PCBs fabrication. The utilization of gold finger PCBs demands a heightened level of manufacturing precision, where a lack of expertise can potentially result in issues such as blackening, whitening, contamination, lateral erosion, scratches, and more.

Benefiting from extensive experience in the field, Rocket PCB has amassed a wealth of knowledge spanning numerous years. This expertise is exemplified through meticulous process optimization, encompassing aspects such as film alignment, liquid concentration control, and plating parameters. These fine-tuned processes culminate in gold finger PCBs of superior quality, consistently surpassing customer expectations and garnering their acclaim.

A standout feature of Rocket PCB’s offerings is the provision for creating unique PCBA interconnections with motherboards, while also allowing for ease of replacement. This innovation is accomplished through the design of gold fingers that emulate the relationship between power plugs and sockets. The inherent conductivity and robustness of gold play a pivotal role in this design, ensuring reliable conductivity without succumbing to oxidation. Furthermore, gold’s exceptional wear resistance guarantees sustained performance, even after frequent insertions.

In essence, the term “gold finger” denotes the practice of plating these fingers with 5–30u” of hard gold. Hard gold, renowned for its remarkable wear resistance, can withstand up to 20,000 insertions without compromising quality, provided it is at least 5u” thick. It’s important to note that while hard gold offers unparalleled durability, its intricate manufacturing process and higher gold salt consumption contribute to elevated costs. In scenarios where frequent insertions are not a requirement, many PCBs can opt for immersion gold plating as a viable alternative. This approach, also known as soft gold, involves a gold thickness of 1–3 u”, effectively reducing PCB procurement costs without compromising on performance.

In conclusion, Rocket PCB’s proficiency in crafting Gold Finger PCBs reflects their commitment to enhancing connectivity and durability within the realm of PCB manufacturing. With a focus on intricate process optimization, unparalleled expertise, and the strategic use of gold, Rocket PCB stands as a driving force in delivering PCB solutions that not only meet but exceed customer expectations.