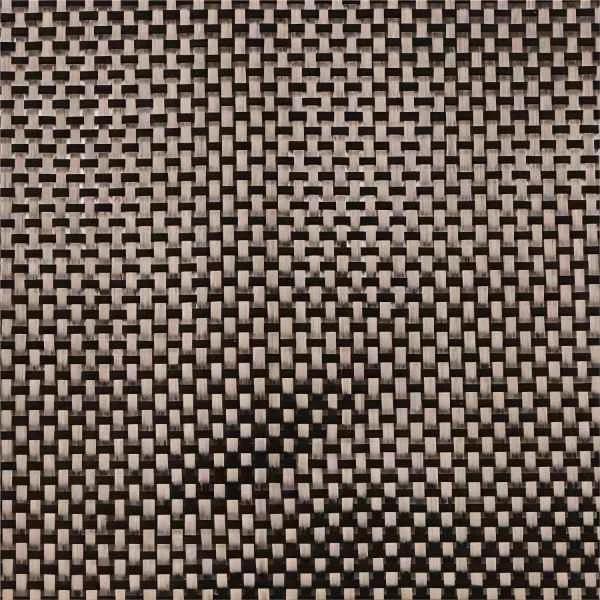

aramid woven tape is a new type of non-woven material, which is different from the traditional weft weaving method, and does not need to go through the weaving machine, but is formed by the interleaving and bonding of the fiber web. aramid woven tape has many advantages, but it also has some disadvantages. The following is a detailed analysis of the advantages and disadvantages of aramid woven tape.

I. Advantages

1, high strength and rigidity

aramid woven tape uses a special manufacturing process to make its fibers interlace with each other and bond firmly, so it has high strength and rigidity, which is very suitable for applications requiring high strength.

2. Light weight

Compared to conventional textile materials, aramid woven tape is very light in weight, but has the same or even better strength and rigidity as traditional materials. In aerospace, armored vehicles and other applications, the lightweight and performance of aramid woven tape can greatly improve the performance of these devices.

3, anti-elasticity

aramid woven tape also has excellent bulletproof performance. It has broad application prospects in special operations and bulletproof equipment.

4, easy to process

aramid woven tape is manufactured by melting or resin processes, so it is very easy to insert and press

Mold, injection molding and other manufacturing processes, improve production efficiency.

5, excellent corrosion resistance

aramid woven tape is generally made of glass fiber, carbon fiber, aramid and other corrosion-resistant materials, so it has excellent corrosion resistance.

aramid woven tape https://www.hzcomposite.com/Aramid-Fiber-Woven-Tape